ADDITIVES

(9 Items)

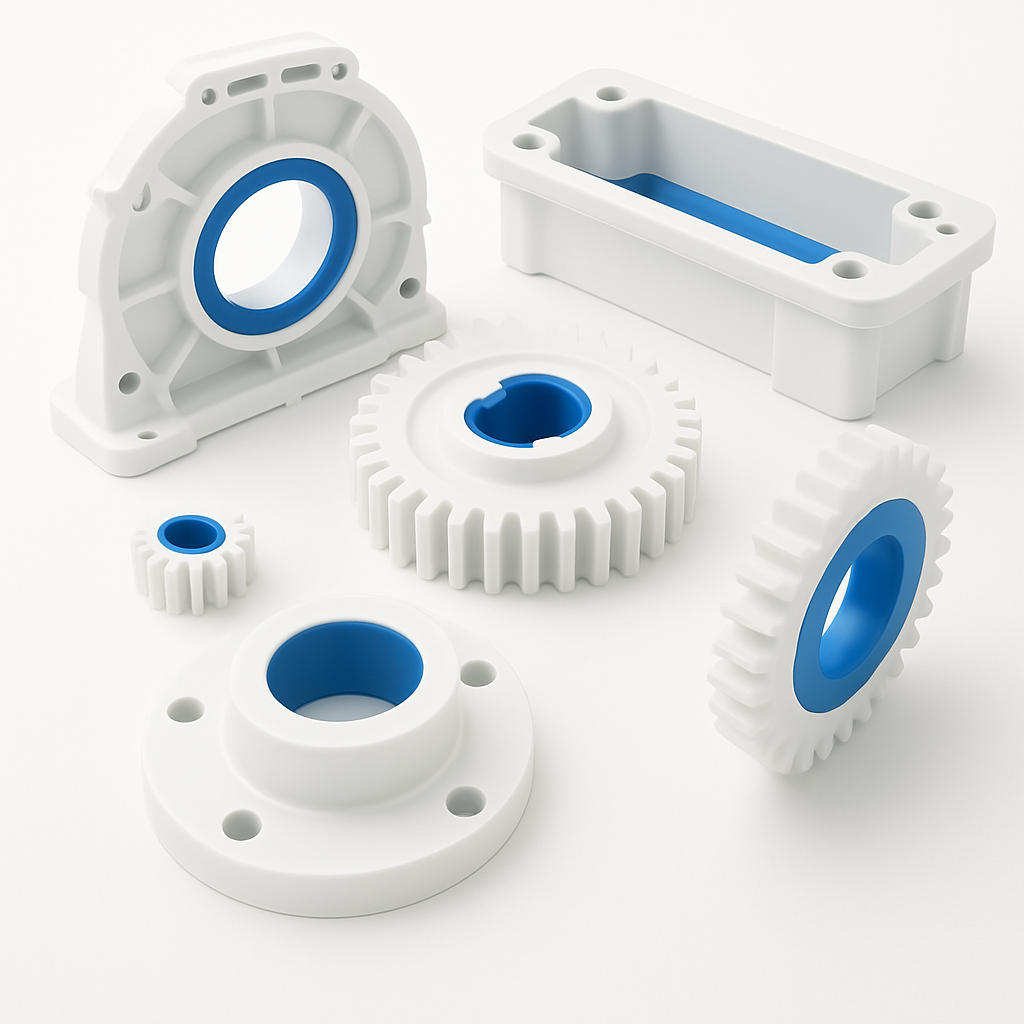

ENGINEERING PLASTIC

(82 Items)

MASTERBATCH

(4 Items)

OFF GRADE

(1 Items)

Polyethylene (PE)

(381 Items)

Polyethylene Terephthalate (PET)

(20 Items)

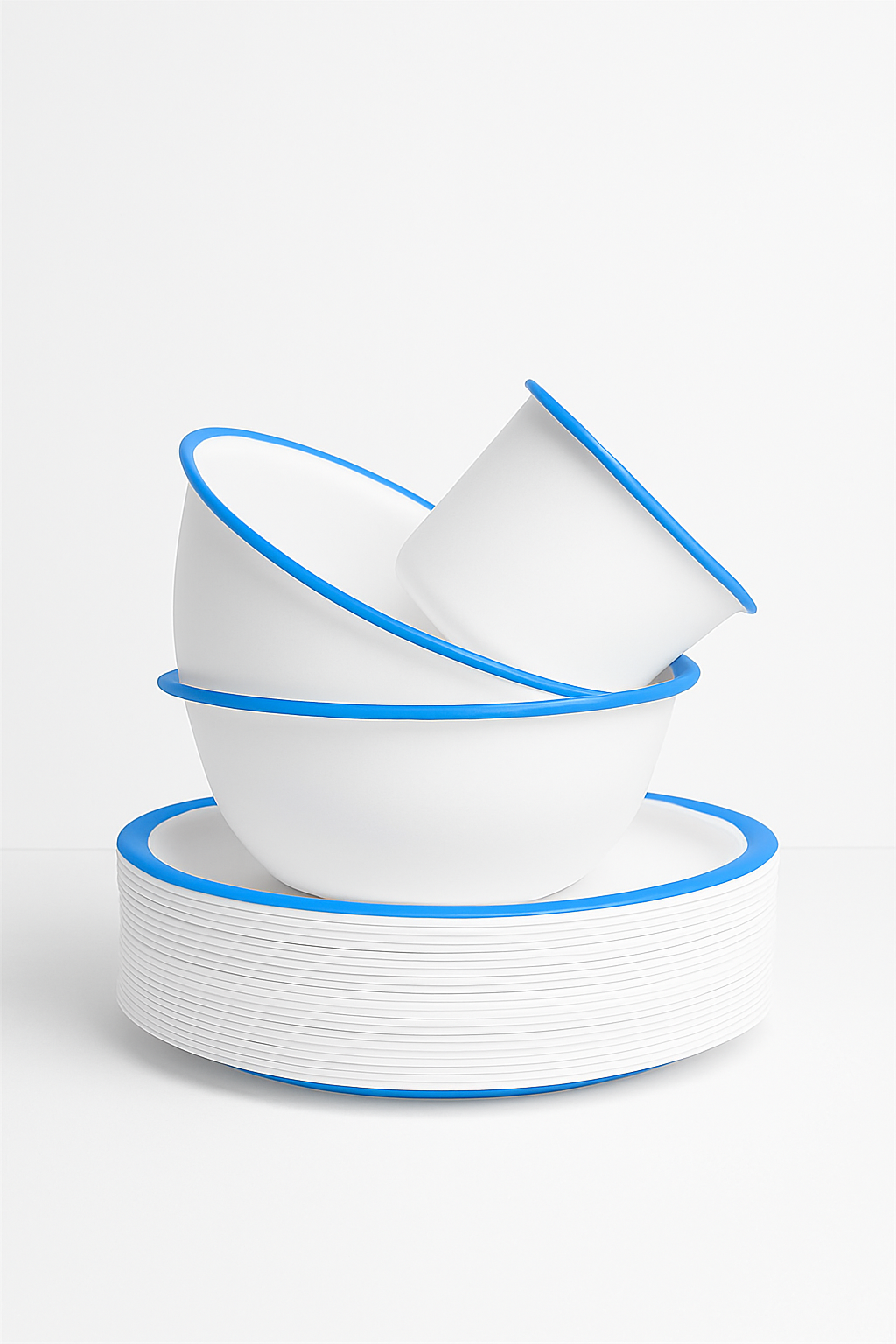

Polypropylene (PP)

(525 Items)

Polystyrene (PS)

(15 Items)

Polyvinyl Chloride (PVC)

(5 Items)

Recycled

(1 Items)